Product specifications

• Model : H2 Spark.

• Power consumption: 80W.

• Concentration of dissolved hydrogen: more than 1000 ppb.

• ORP: between -450 ~ -580mV.

• Work temperature : 5 ~ 40 ℃.

• Work Pressure : 0 ~ 0.6 Mpa (0 ~ 6.1kg/cm2).

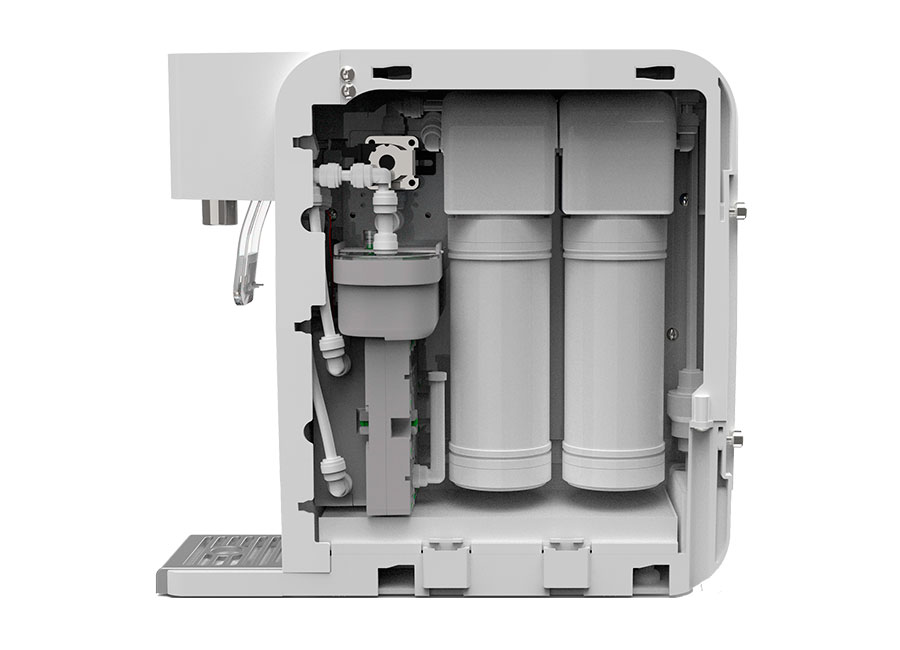

• Valid water type : reverse osmosis water or bottled water.

• Equipment weight : approximate 4.5 Kg.

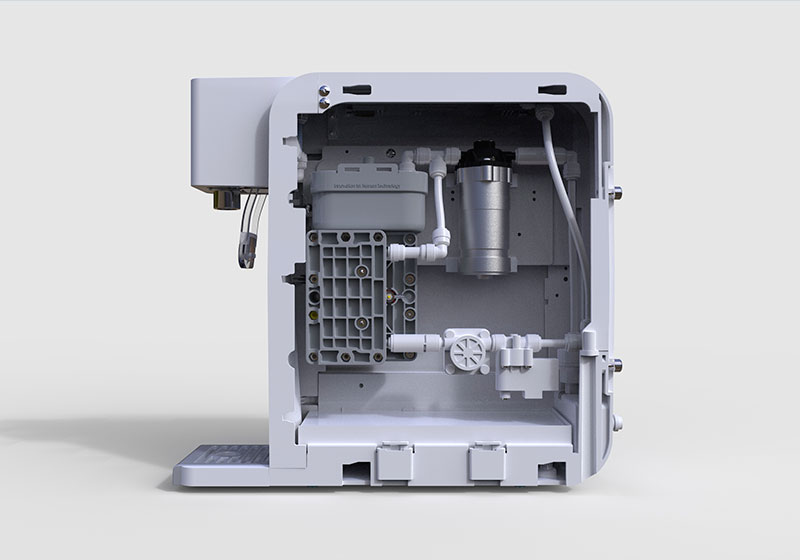

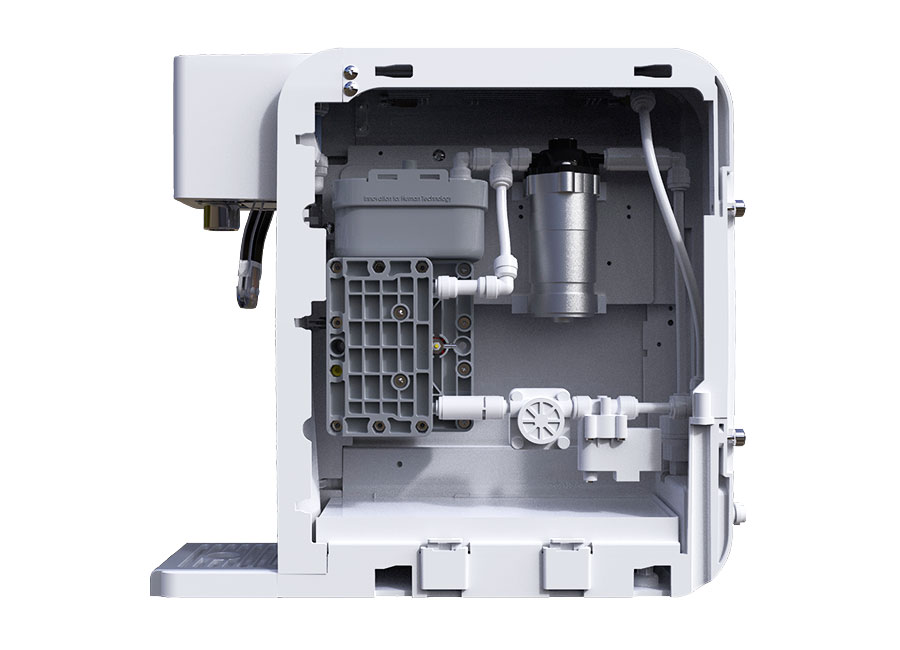

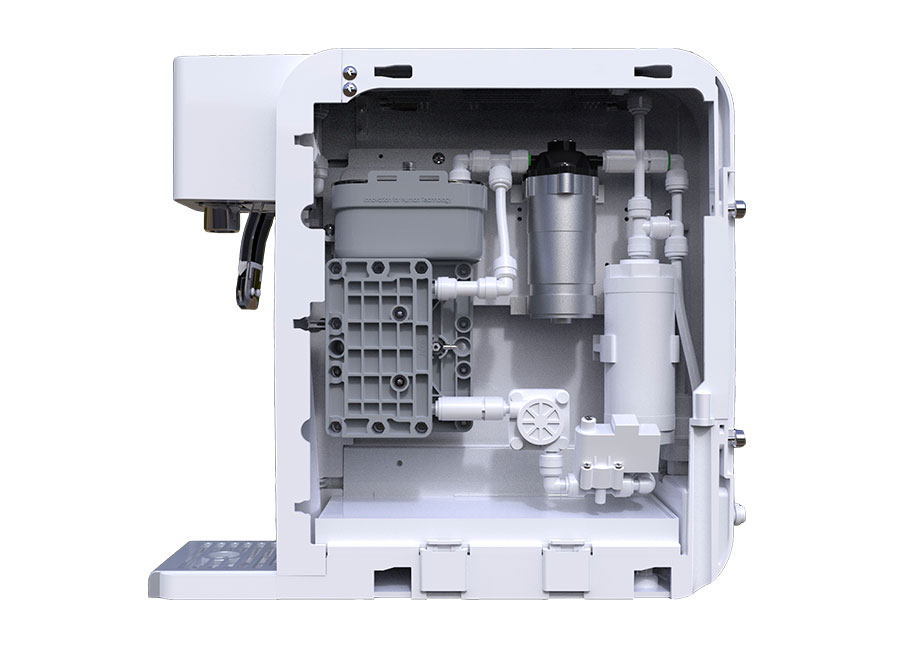

• Equipment dimensions: W 119 × D363 × H 340 mm.

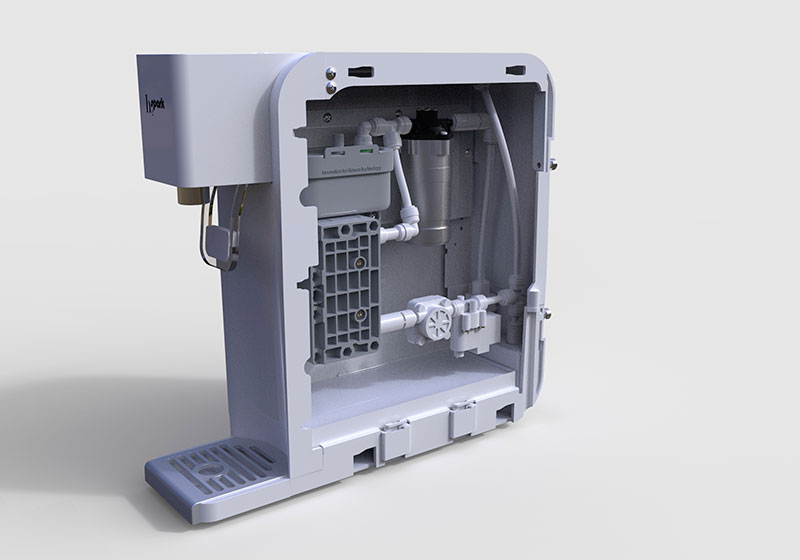

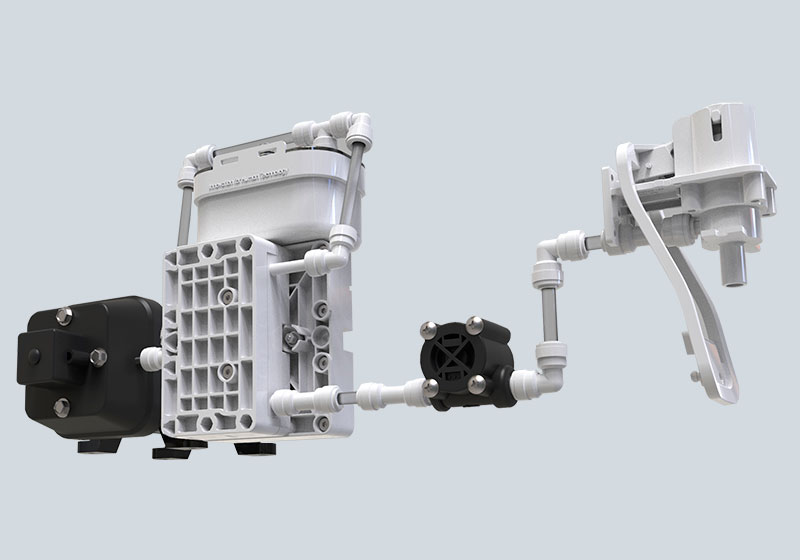

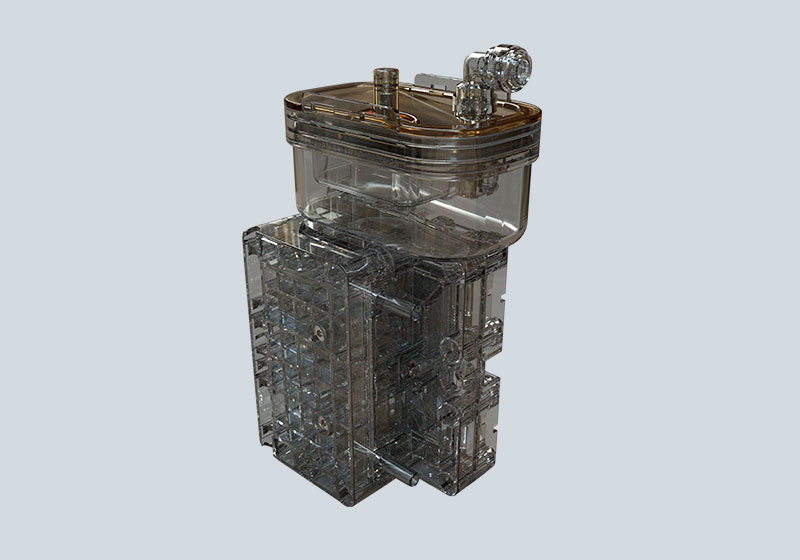

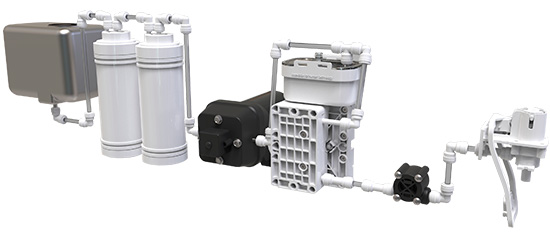

• Hydrogen generation method: water mixture with hydrogen in real-time.

• Input and output voltage : 100V ~ 240V / 50 ~ 60 Hz.

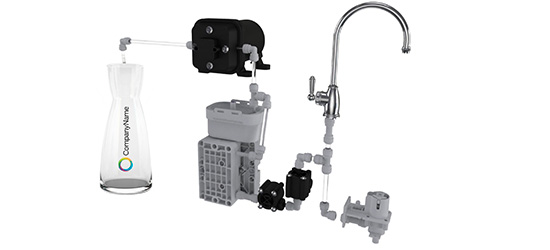

• Output method: faucet or dispenser.

• Use: domestic.

Hydrogenated water not portable

H2 Spark

Characteristics

• Generates high concentration hydrogenated water in real time.

• High concentration of dissolved hydrogen: 1000 ppb or more.

• It maintains the concentration of dissolved hydrogen long.

• Discharge OH- and ozone using the PEM system (no odor of ozone in the water).

• It ensures the durability performance of the electrolyser by using osmotized water or bottled water.

• Ensure electrical stability while using low voltage direct current.